The traditional perceptions of manufacturing as an industry primarily focused on mass production have become outdated. While materials and assembly – bashing steel, fitting parts – is still the crucial function of a manufacturing company, to prosper in a modern business environment requires a wider scope of work characterised by a commitment to innovation within each major business function.

Today’s manufacturing landscape contains a multitude of diverse roles – and with them, a wider range of opportunities for employee development and retention. Trimax Mowing Systems in Greerton, Tauranga has adopted such a holistic view in their company structure, incorporating design, engineering, sales, service, marketing, business development, and distribution along with their production capabilities.

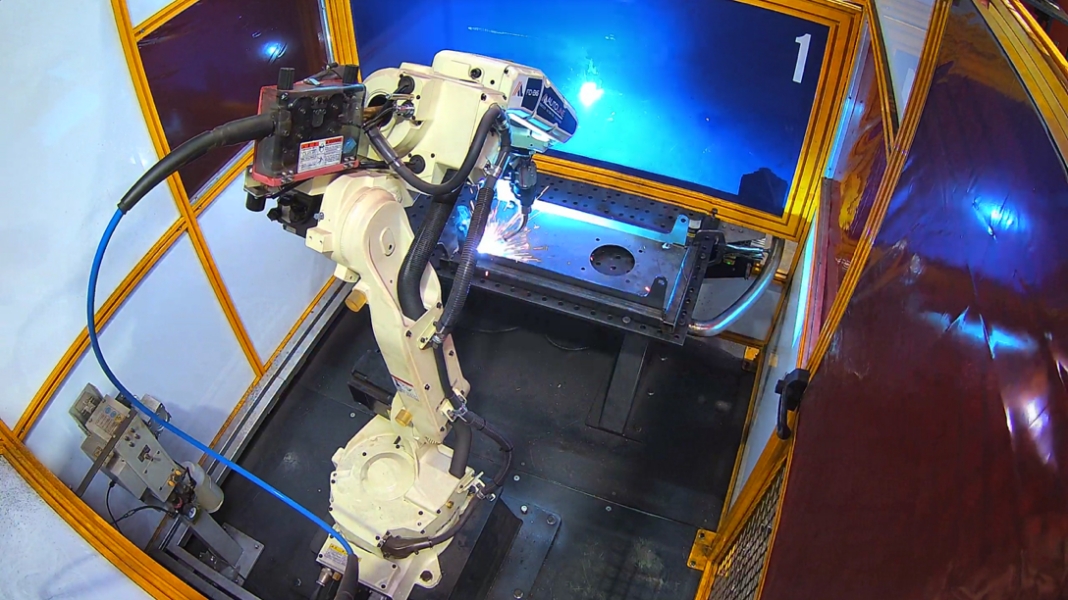

With the introduction of our welding robots, we’ve been able to transition a valuable skill set into a role with less physical demand and increased longevity. Our welders can train, develop, and extend their careers, and Trimax can provide more opportunities for a wider workforce.

Michael Sievwright, CEO of Trimax Mowing Systems, summarises: “Trimax is a customer-driven company that manufactures, not only a manufacturer.” Here Michael outlines three key strategies that set Trimax apart from their manufacturing contemporaries.

Embracing process and technology

“In the New Zealand manufacturing environment, we have to invest in effective process and automation. Developing thorough standard operating procedures, designing for manufacture, and incorporating automation are essential for us to advance in the competitive global market.”

Driving acceptance for new processes, especially in a company like Trimax that has been actively in production for over 40 years, can sometimes pose a challenge.

Working with the operations team to communicate the reasoning behind the changes and the benefits that they bring to the company, as well as encouraging active collaboration from team members throughout the integration process, has allowed Trimax to successfully integrate new systems with eager cooperation from experienced staff.

Trimax emphasises automation as a tool and an investment not only for production but for staff development. The recent incorporation of welding robots in the New Zealand factory has been successfully implemented with this long-term upskilling approach.

“Welding is quite physical. With the introduction of our welding robots, we’ve been able to transition a valuable skill set into a role with less physical demand and increased longevity. Our welders can train, develop, and extend their careers, and Trimax can provide more opportunities for a wider workforce.”

The addition of some automated work functions has also allowed Trimax to increase their productivity. “The robots are allowing our team to achieve two to three times the output that we could achieve with traditional welding alone, and the machinery isn’t even running at full capacity.”

Applying globally learned lessons

Trimax’s target customer bases are closely connected to their land, placing inherent value on the ability to be physically close to their markets. The focus on relationship building and collaborative problem solving throughout the Trimax sales process also necessitates a fixed local presence in the locations where the company plans to grow and expand their business.

Since the mid-1980s, Trimax has established a global infrastructure that includes local staff and facilities not only in New Zealand but also in Australia, the United Kingdom, and the United States.

“We have facilities in those countries. We manufacture in those countries. But New Zealand is still a core part of our business and operation. Through our internal knowledge sharing we’re able to bring value from our experiences in other markets back to our operations in the Bay of Plenty, and vice versa.”

Trimax hosts their engineering team and knowledge base here in New Zealand, serving as a centralised hub for their global operations. Steady communication with their international facilities enables Trimax to centrally incorporate beneficial developments across all their locations and promotes a consistent customer experience no matter where in the world a customer is based.

This global consistency is especially important due to Trimax’s high global export volumes. With manufacturing facilities firmly established in three out of four of their major markets, product can be moved around the world to meet global demand without concern over differing manufacturing methodologies or quality between mowers produced in different factories.

Planning for continuous development

The outlook for New Zealand’s manufacturing sector is constantly evolving as new technological and procedural developments gain traction. Staying at the forefront of the industry entails a high level of vigilance to up-and-coming trends and the foresight to understand how new technologies might be applied within the framework of Trimax’s business.

In such situations, the development of a community of practice can be mutually beneficial to all those involved. “The Bay of Plenty has a surprisingly high concentration of high-value manufacturing businesses. We can grow our region’s capability by coming together as a community to share our knowledge and best practices.”

Most important is maintaining the right mindset. Recognising that there is always room for improvement and remaining open to the possibility of finding a better way prevents companies like Trimax from getting stagnant and increases the agility of the overall business. Trimax underscores this tenant through one of their main pillars of culture: Stay curious and humble.