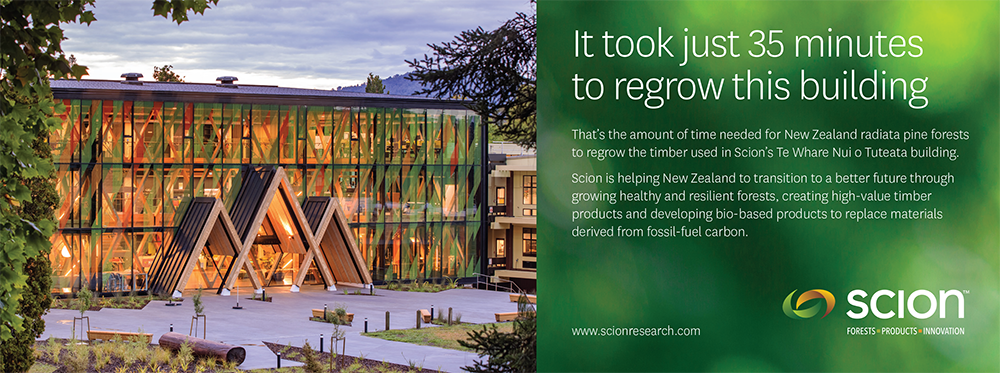

Research and new technologies are enabling forestry to be the engine of a circular bioeconomy for New Zealand.

The Forestry and Wood Processing Industry Transformation Plan (ITP), recently launched at Fieldays, has created opportunities for Scion to lead the way with research that will drive the development of new manufacturing sectors and low-carbon products. These efforts will help New Zealand meet its net-zero emissions targets by 2050.

Forestry is already recognised as a vital means of tackling climate change. It plays its part in two ways: removing CO2 from the atmosphere and reducing greenhouse gas emissions by substituting products, fuels and energy made from fossil fuels with renewable wood and fibre-based alternatives.

For 75 years, Scion’s research has created healthier and more resilient planted forests and productive timber industries. Evolving technology is making forestry science more precise than ever, offering researchers the chance to unlock the forestry and wood processing sectors’ true potential.

Scion chief executive Dr Julian Elder says the Government’s plan for forestry reinforces the relevance of Scion’s Strategy for 2030: Right tree, right place, right purpose. This formula will support New Zealand’s transition to a circular bioeconomy and stimulate its recovery in regions hardest hit from the effects of Covid-19.

“The ITP has underlined the opportunities for industry, iwi and New Zealand when we all work together to harness the power of trees. We can create a carbon-neutral future and grow the economy.

“Our bio-based research is challenging everyone to re-think how we make better use of our woody biomass. It’s a future where every inch of a tree can be used to create high-value products, offering an alternative to products made from fossil fuels. This will deliver true prosperity for the regions.”

Benefits of a circular bioeconomy

Elder cares deeply about ensuring that the “take, make, waste” linear economic model is replaced by one where the word ‘waste’ is redundant.

Scion is among the global leaders in this circular bioeconomy approach – a model where waste from one process becomes feedstock for another. The concept aims to design out waste, keep materials in use for longer and regenerate ecosystems.

As well as helping New Zealand and the world meet its climate change targets, a circular bioeconomy is a $30 billion economic opportunity, says Elder.

“It’s this environment that provides a mosaic of activity for regional New Zealand to thrive, through emerging bio-based manufacturing and the creation of new high-value products from what we currently consider waste.”

Growth through distributed manufacturing

Scion’s research and technical support has underpinned the wood processing sector that New Zealand has today. More than 60% of harvested wood is exported as logs for other countries to process and add value. In addition, about 4 million tonnes of woody material is left behind in forests following harvesting and forest growing operations.

Scientists are now finding new ways to use these residual woody resources, including forestry slash, to increase exports, create jobs, drive innovation and adapt to climate change. Key to this will be lowering the extraction and transport costs of harvesting residues, says Elder.

To deliver on this, Scion is leading the development of a technique called ‘Distributed manufacturing’ which involves placing small processing units, or mini factories, on or near forestry harvest sites.

Distributed manufacturing is one solution to increase on-shore manufacturing and can play a major role in the forest-based value chain. Essentially, these mini factories can be tailored to process biomass such as forest wood waste, horticultural and farm shelterbelt thinnings or crop residues into high-value wood-based products, biochemicals or pharmaceuticals.

“Imagine a factory that fits in a shipping container – compact and mobile,” he says. “These can be strategically positioned within a forest, orchard or farm where the waste is created. These factories can perform novel scalable processes such as biochemical conversion, pyrolysis and pulping. The choice of process depends on inputs and the product being made.”

Creating value-add products

Scion scientists are already investigating the feasibility of a bark biorefinery that could extract tannins from bark stripped from pine trees after they’re felled for export. This follows a proof-of-concept study that showed how hides can be successfully tanned using pine bark tannins. These could replace imported tannins that are less environmentally friendly and be used to create other high-value chemicals for industry.

“This is just one example of how woody waste can be used to accelerate our economic growth and mitigate climate change. It’s an exciting time to be in forestry.”