In 2021, the community of Whakatane was devasted to learn that the mill – one of the town’s biggest and long standing employers – was proposing to shut down at short notice.

Along came the Smurfit Consortium, which signed a purchase agreement at the eleventh hour and the Whakatane Mill, WML, continued to produce folding box board and are proudly the only producer of this type of board in Oceania.

The consortium was led by Ian Halliday, a longstanding business expert in the Pulp and Paper sector who was able to travel to NZ in April 2021 amidst the Covid disruption and identify what an asset the mill was.

Ian understood that if the mill focused on what it was built for, producing folding box board rather than liquid packaging board, that the mill would be a profitable business.

To produce board, paper mills run 365 days of a year, 24hrs a day. Water, pulp and energy are the key resources required along with a paper machine that can be up to 150m in length and 10m wide.

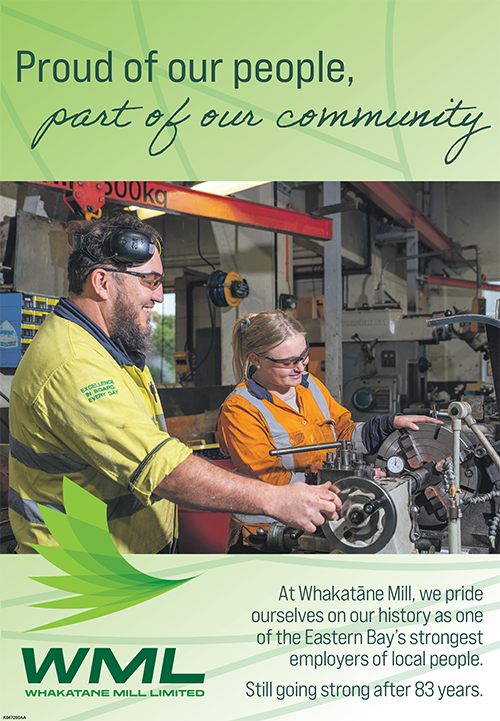

At WML, a team of 180 is employed across paper making, technical, engineering, supply chain, finance, HR and sales. A minimum of 15 loads per day leave the mill to take product to either Auckland based customers or Tauranga Port to ship rolls of board all over the world.

Ian, the Executive Chairman of the mill today recently appointed Ron Hooper to the role of Chief Executive in June this year.

Ron is a highly experienced and well-regarded business leader from the food and packaging sectors, having work previously for major multinational brands such as Griffins, Nestle and Mars. An Australian by birth, Ron has lived the past 12 years in Auckland and for the new role at the mill, has relocated to the region to immerse himself in the business and local community.

“Being part of this community is a key focus for my wife and I,” says Ron, “The mill has a tremendous legacy in the Bay of Plenty area. It’s touched the lives of so many families and provided employment and income for generations. Going forward we want to make the mill a destination employer in the region, to really create an environment where people come to work to contribute and be valued and then to push that goodwill and benefit further into the community so more in the region can benefit”.

The mill is now embarking on a major expansion project as it invests $60million to increase capacity from 150,000T to over 200,000T of folding box board which is to be led by Ron.

Nothing is ever done on the small scale at WML and by July 2023 when the project is in full swing, the mill will require a 28 day closure to allow the 400+ contractors access to the machine with specialised equipment being sourced from countries such as Germany, Italy, the US and Finland.

The project is now well into the planning phase, machinery has already started to arrive onsite and Ron is excited by the challenge of the new era the mill is entering.

“We work in a sustainable, renewable industry, with forward momentum being driven by consumers to have recyclable packaging and the removal of single use plastic from the environment and the products produced by our mill fit that brief”

With over 80% of the volume produced at the mill destined for overseas markets including Australia, Italy, Columbia, the US and the Philippines, the mill works hard in not only promoting itself when selling but also the aspect of being from NZ and the core raw material, trees, being sourced from within 120km radius of the site.

Trees are the only truly renewable resource and in NZ the forestry industry and related wood processing industries (including WML) provide tens of thousands of jobs. 1.7 million hectares in NZ is planted in plantation forests and the future for the resource is strong as the world moves towards more sustainable and biological-based economy.

Hence Ron and his team are extremely upbeat about the mill investment as well as the healthy future ahead for the business. “together we want to create a responsible, sustainable business that will benefit the community and the mill family for decades to come”