Converting partly digested grass from the stomachs of slaughtered cattle into biogas that could be used to sustainably heat commercial greenhouses is the focus of a new 14-month study at Scion.

It’s hoped the partly digested grass can one day be blended with food waste to develop a powerful new recipe to enhance bioenergy production for industry – making it less reliant on fossil fuels, saving money and benefiting the environment.

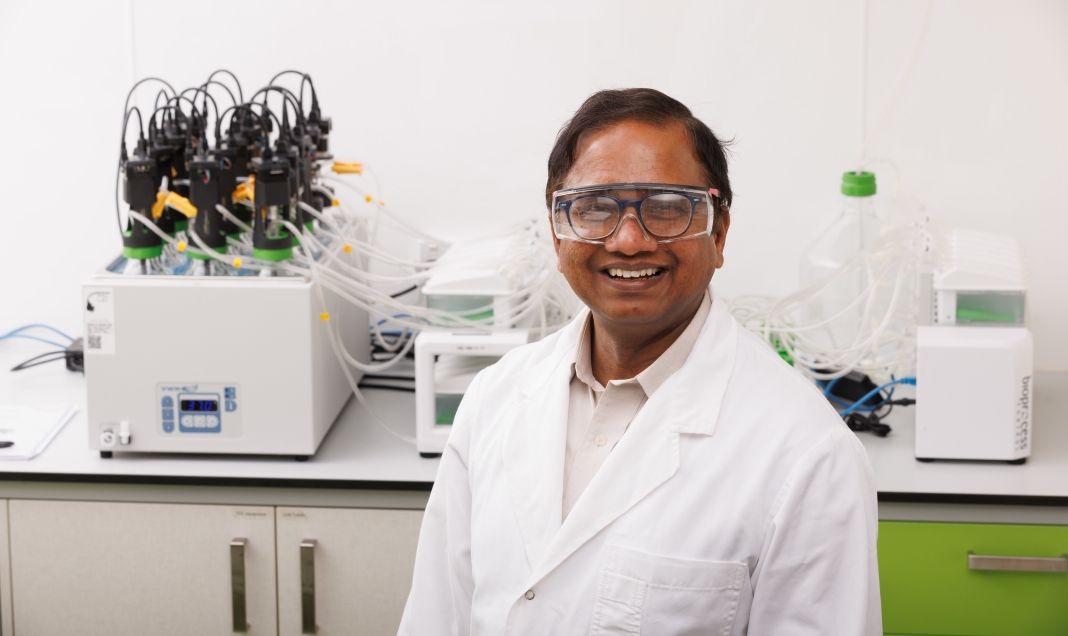

Senior scientist and project leader Dr Suren Wijeyekoon says it is well known that cows produce a lot of methane gas when they belch after grass is digested by enzymes in their stomachs.

Taking the same grass, known as ‘paunch grass’, from slaughtered animal stomachs and using it to produce methane-rich biogas is a research opportunity worth exploring for future bioenergy production replacing natural gas, he adds.

“Each cow has about 10-15kg of partly digested grass in their first stomach when they arrive in an abattoir; that grass normally is disposed of by meat processing companies, which comes at a cost. Our research is looking at the potential to use that waste product to produce biogas at scale, taking it from a small batch to a large pilot study. If successful, it’s research that can be commercially adopted by Ecogas.”

The research involving Ecogas, AgResearch and the Bioresource Processing Alliance (BPA) builds on 2017- 2018 Scion, Plant and Food Research and BPA research that piloted and de-risked the technology being used in New Zealand’s first large-scale food waste-to-bioenergy facility at Reporoa.

Scion provided bioenergy expertise to the facility’s early planning and development.

Once up and running by January 2023, the $30 million state-of-the-art facility will turn 75,000 tonnes of organic waste from businesses and kerbside food scrap collections throughout the North Island into sustainable and renewable clean energy. Owned and operated by Ecogas, the new anaerobic digestion plant sits on 2 hectares of farmland. After commissioning, food waste will be converted into biogas, which can be used to heat nearby greenhouses, with carbon dioxide pumped in to enhance plant growth. Biofertiliser produced at the site can also be applied onto more than 1500 hectares of productive farmland, replacing imported and manufactured synthetic fertilisers.

Dr Wijeyekoon says the paunch grass biogas study started in July and will be carried out at three different scales. It will evaluate how much gas can be produced from paunch, and how scientists can enhance that production through various grass ‘pre-treatment’ methods. Successful methods will be scaled up from batch to continuous pilot scale.

Silver Fern Farms provides the fresh paunch grass for the study. Scion scientists are then deploying Scion’s new ‘biomethane potential test kit’ to assess the biogas production, which is made up of about 60 percent methane, and 40 percent carbon dioxide.

Testing will be complete in October 2023. If successful, it’s hoped the project will be commercially adopted.

Dr Wijeyekoon says a long-term goal is to blend the paunch grass with food waste to maximise biogas generation.

“Grass is made up of mostly cellulose and is metabolised slowly. Food waste is fast digesting; together you will improve the digestion of grass.”

“Ideally, you need the right cocktail to get the bugs working optimally – that’s the end game.”

The $385,000 study has been jointly funded by Ecogas and the Bioresource Processing Alliance which works with New Zealand’s primary sector and science partners, including Scion, to get better value out of biological by-products.

AgResearch is also involved in the study by exploring the potential of ‘paunch liquor’ to be used as a pet food ingredient. The liquor is considered a valuable source of proteins, minerals and vitamins for cats and dogs.

In another part of the project, Scion scientists will also test the digestate, the material left over after the paunch grass is digested in the bioreactors, for its potential as a biofertiliser. The team and Ecogas will partner with a company to carry out field trials to assess pasture growth after digestate is applied.

Dr Wijeyekoon says the study is a great example of Scion’s research exploring the benefits of a circular bioeconomy.

“There are waste management costs for the disposal of paunch grass currently. Using that one feedstock or waste stream, we can explore a number of new opportunities: bioenergy production, bioCO2 for photosynthesis in greenhouses, digestate for biofertiliser and pet food ingredient production.”

The benefits to the environment and industry are wide ranging. As well as reducing costs and climate change emissions from meat processing companies by diverting waste from landfill or composting, the biogas produced could also satisfy the heat demands of abattoirs in the future, he adds.

Ecogas General Manager Alzbeta Bouskova says the company is excited to partner with Scion in the study and explore the potential of paunch grass as a new clean energy feedstock and, in the process, assist the meat industry with transition to sustainable and circular principles.

“Ecogas is pleased with the opportunity to continue to build commercially desired technical knowledge,” Bouskova says.

Related: Scion develops H&R solution to tackle plastic waste for nurseries