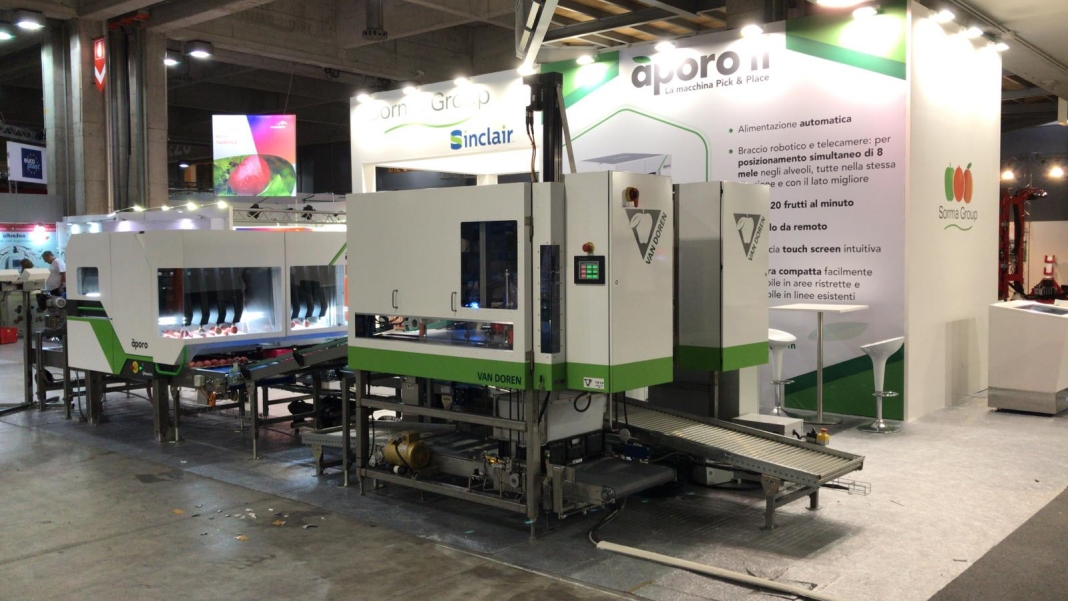

The pairing of two cutting edge robotic technologies is set to slash labour requirements in post-harvest facilities across the globe, and the happy couple debuted in Bolzano, Italy on 17 November. Global Pac Technologies displayed a working demonstration of the Aporo™ II robotic apple packer and just released Carton Optimization Robot (COR) at the world leading apple trade event, Interpoma.

The Aporo™ produce packer, designed and manufactured in New Zealand by Robotics Plus, was launched back in 2018 with the mission of reducing the labour required to place fruit into trays.

This then focused the customers attention on their next challenge – getting the full trays into cartons. US head-quartered Van Doren Sales Inc took up the challenge and after several iterations, the COR was heavily tested in both hemispheres, and is now ready to launch.

While Aporo™ and COR are modular pieces of equipment, both have been designed to integrate up and downstream in the packhouse. Integrated together, they remove the need for labour to place fruit in trays and get trays into cartons.

“This means that pack house operators can redeploy their labour to value adding activities, rather than the repetitive or mundane ones,” says Cameron McInness, director of Global Pac Technologies who distribute both robots globally. Coupled together, the two technologies can pack a minimum of one carton per minute per belt, or two cartons per double belt, without any manual labour.

“Our business is customer led. We listen to their pain points, and we look for solutions,” adds Cameron. “Depending on the nature of the produce and the packhouse configuration, the combination of these two technologies can see a reduction of up to six employees per double belt which is a huge win for the customer.”

The post-harvest industry has been grappling with labour challenges globally. Whether it be rising costs or access to labour, the potential negative outcome is the same – a risk that a crop cannot be packed and shipped.